America’s Finest

America’s Finest is a Skipsteknisk ST-116XL design catcher-processor vessel, built in Anacortes, Washington at Dakota Creek Industries (Hull #63). An engineering marvel, with the most up to date fishing/shipping technology, she’s just joined the fleet in February of 2019

Technical Specifications

Owner: America’s Finest Fishing, LLC

Particulars:

Official No. 1276760

IMO No. 9765548

FCC Call Sign WFIK

Length LOA 264 feet

Beam (width) 51 feet

Registered Tonnage 3,640 Gross Tons

Class DNV-GL 1A1 E0 Stern Trawler, Hull Ice Class 1B

Steel Hull Delivered in 2019 by Dakota Creek Industries, Anacortes, WA

Propulsion 1 x 6,436 hp MAN 8LCR32 Tier II, ABB turbo main engine, single propeller.

Freezing System Ammonia, 2 x Micom 475 hp compressors, 1x Micom 125hp for RSW.

Product 20kg packaged blocks frozen, trawl caught, H&G flatfish, Cod, Pollock

Freezing Speed Core temperature to

-20C in 75-90 min.

Daily production capacity

140MT/day

(308,560 lbs/day)

(617,120 meals/day)

Cargo hold (-25C)

55,000 cases,

(1,200 MT)

(2,424,400 lbs)

(4,848,800 meals)

Crew Size 50

Build Story

Factory Fishing Vessel

This US flagged Amendment 80 replacement vessel designed for Fishermen’s Finest by Skipsteknisk AS (ST-116XL) specifically for catching and producing frozen at sea white fish products, groundfish, including yellowfin sole and rock sole species. Operations will be in the Gulf of Alaska and Bering Sea. The ship will be built to class DNV GL rules for fishing vessels including clean class, and have hull notation +1A1, Ice 1B. Powered by MAN 8L32/44CR diesel engine, utilizing the latest Common Rail technology. This will be the first ST-116XL design to operate in the United States.

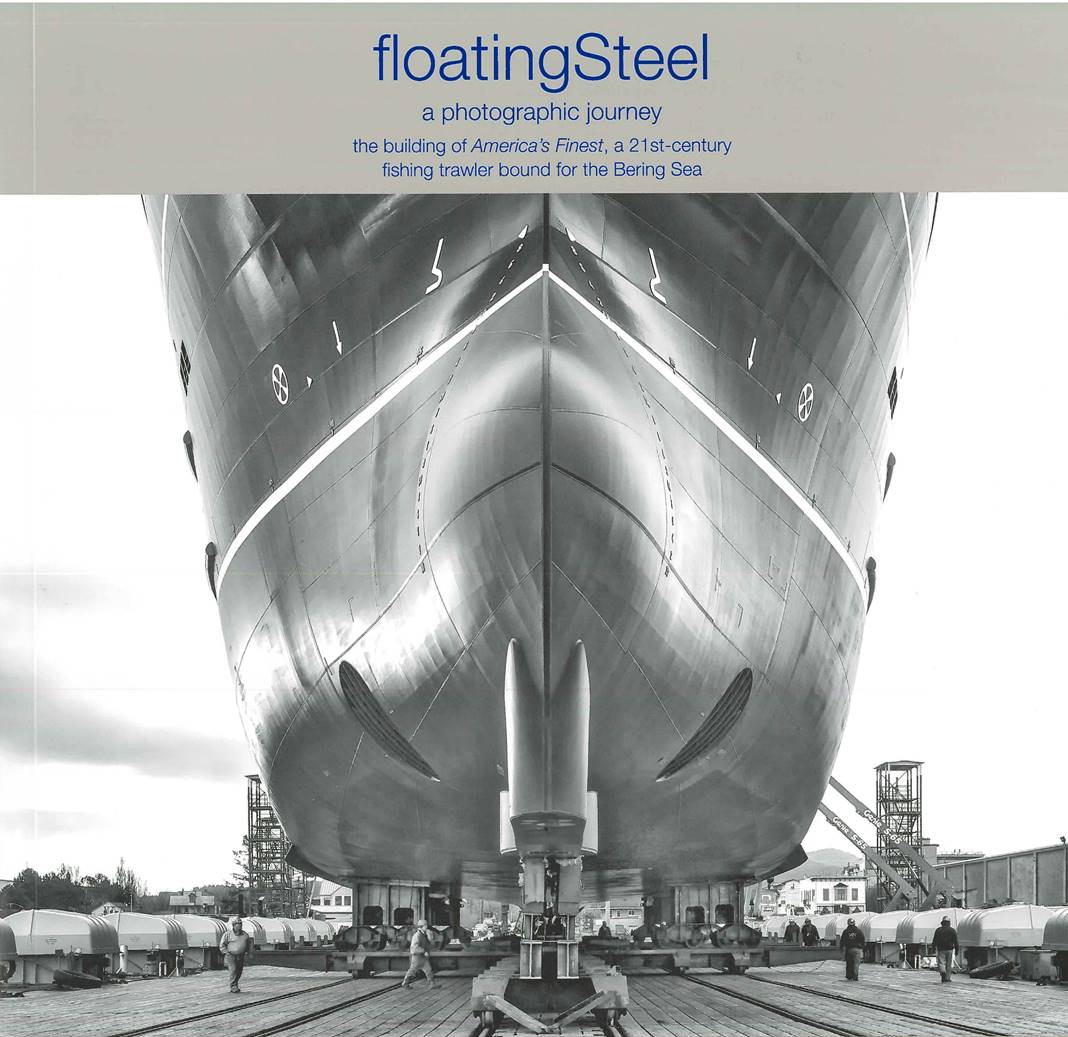

Floating steel

Floating Steel — a project that’s purpose and intent is to produce a pictorial journey and adjoining information of a complete Bering Sea Fishing Stern Trawlers construction from start to finish. A continuing update will be posted (weekly) on this site. The entire process all shot in artful cut glass black and white accompanied with insightful informational commentary by photographer Harry von Stark